Wholesale OEM Ppr Pipe Fitting - OEM Peek Ring Seals – Lucky Star Seal Detail:

1.Heat-resistance

PEEK has a higher glass transition temperature and melting point (334℃). It is one of the reasons that it can be a reliable application in the requirement of the heat. Its heat load variable-temperature can be 316℃, continuous use temperature is 260℃.

2.Mechanical Properties

PEEK is the plastic that strikes a balance between toughness and rigidity. Especially, it has an excellent fatigue resistance against alternating stress that is the most talented of all plastics, and it can be comparable with alloys.

3.Self-lubricating

PEEK has outstanding sliding characteristics in all plastics; it is suitable for stringent requirements for low coefficient of friction and resistance to friction used. Especially, the self-lubricating properties of PEEK will be better if it is modified by carbon fiber and graphite mixed in the proportion of each of them.

4.Chemical Resistance (corrosion resistance)

PEEK has excellent chemical resistance. In ordinary chemicals, it can be dissolved or damaged only by concentrated sulfuric acid; its corrosion resistance is similar to those of steel and nickel.

5.Flame Retardant

PEEK is a very stable polymer. The 1.45mm thick samples can achieve the highest standard of fire retardant without adding any fire retardant.

6.Stripping Resistance

PEEK has good stripping resistance; therefore, it can be made into thin wires or electromagnetic wire coating, and it can be used in harsh conditions.

7.Fatigue Resistance

PEEK has the best fatigue resistance among all resins.

8.Radiation Resistance

PEEK has a very strong γ irradiated resistance, which is stronger than the radiation resistance of polystyrene, which is the best one among generic resin. It can be made into high-performance wiring that can still make good insulation capability when γ irradiation is at doses of 1100Mrad.

9.Hydrolysis Resistance

PEEK and its composites will not be affected chemically by water and high-pressure steam. The products that are made from this material will maintain the outstanding characteristics in continuous use in high temperature and high pressure water.

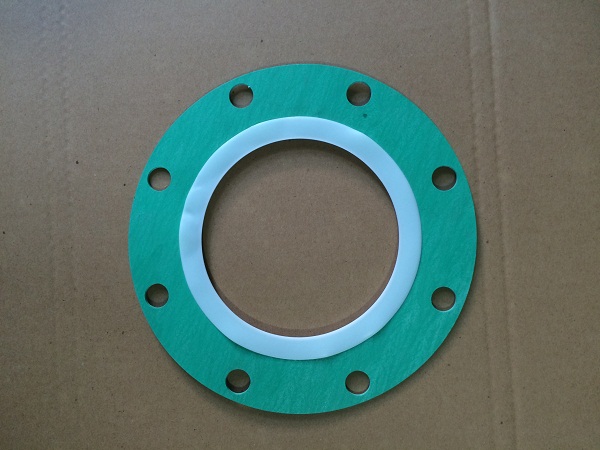

Product detail pictures:

Related Product Guide:

What Is A PTFE Ring Gasket?

Thermal And Chemical Benefits Of PTFE Ring Gaskets

Well-run equipment, expert income workforce, and far better after-sales expert services; We are also a unified large family, anyone stick to the corporate value "unification, dedication, tolerance" for Wholesale OEM Ppr Pipe Fitting - OEM Peek Ring Seals – Lucky Star Seal, The product will supply to all over the world, such as: USA , Manchester , South Korea , During the 10 years of operating, our company always try our best to bring consumption satisfaction for user, built a brand name for ourselves and a solid position in the international market with major partners come from many countries such as Germany, Israel, Ukraine, United Kingdom, Italy, Argentina, France, Brazil, and so on. Last but not least, price of our products are very suitable and have fairly high competition with other companies.

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.

-

Top Suppliers Cast Iron Pump Body - Stainless ...

-

Top Grade Galvanized Pipe Size Chart - Camshaf...

-

OEM Supply Make Enjoyable Life - Cheapest Pric...

-

Supply OEM/ODM Epdm Nbr Ptfe Gasket - Glass Fi...

-

factory Outlets for Air Driven Transfer Slurry ...

-

High Quality for Footvalve Ptfe Envelope Gasket...