Top Grade Ptfe Coated Ring Joint Gasket - China Factory for Dry Break Couplings - 100% virgin PTFE Extrued Rod – Lucky Star Seal – Lucky Star Seal Detail:

Technical Data:

| Properties | Unit | Result |

| Apparent density | g/cm3 | 2.3±0.1 |

| Tensile strength (min) | Mpa | ≥25 |

| Ultimate elongation (min) | % | ≥200 |

| Working Temp | °C | -180 ~ 260 |

| Produce Max. Temp | °C | 385 |

| Melting point | °C | 327 |

| Hardness Rockwell | - | M65 |

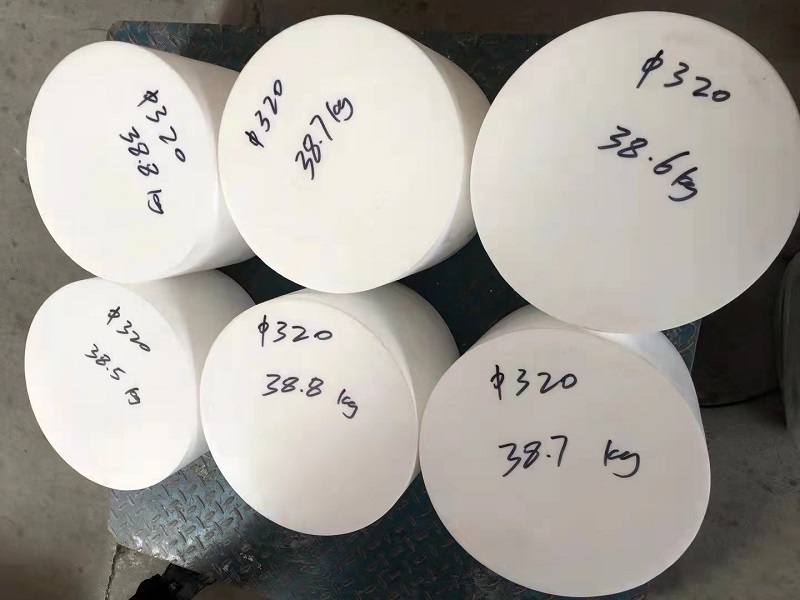

Supply size:

|

Type |

Diameter (mm) |

Length (mm) |

|

Extruded rod |

4–100 |

As customized |

|

110–200 |

As customized |

|

|

Moulded rod |

50–300 |

300 max |

Advantages:

♦ Superior endurance in corrosion

♦ Non-flammable,limited oxygen index is under 90.

♦ Low friction coefficient

♦ Non-viscous, Self-lubricating

♦ Superior endurance in high & low temperature, can be used -200~260℃

♦ High electrical insulation

♦ Atmospheric aging resistance

♦ Low permeability, good gas barrier property

♦ Good physiological compatibility and anti-thrombotic

Applications:

♦ Corrosion resistance: widely used in all chemical containers and parts which contacted with corrosive media, such as tanks, reactors, equipment lining, valves, pumps, fittings, filter materials, separation materials and pipe for corrosive fluids.

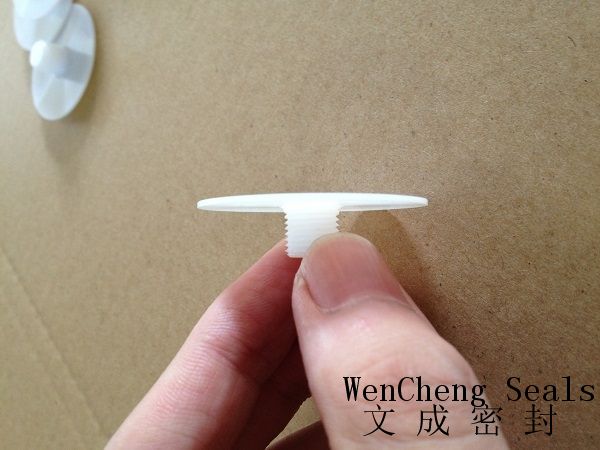

♦ Abrasion resistance: can be used as a self lubricating bearing, piston rings, seal rings, gaskets, valve seats, sliders and rails etc..

♦ Insulation materials: mainly used in the manufacture of various products with high temperature resistance, high-frequency resistance, electrical insulation and arc resistance, such as high-frequency cables, moisture-resistant cables, capacitor coils, insulating cover for wire, etc..

♦ Medical materials: such as artificial blood vessels, heart, esophagus, peritoneum, heart devices, a variety of intubation tubes and catheters.

Product detail pictures:

Related Product Guide:

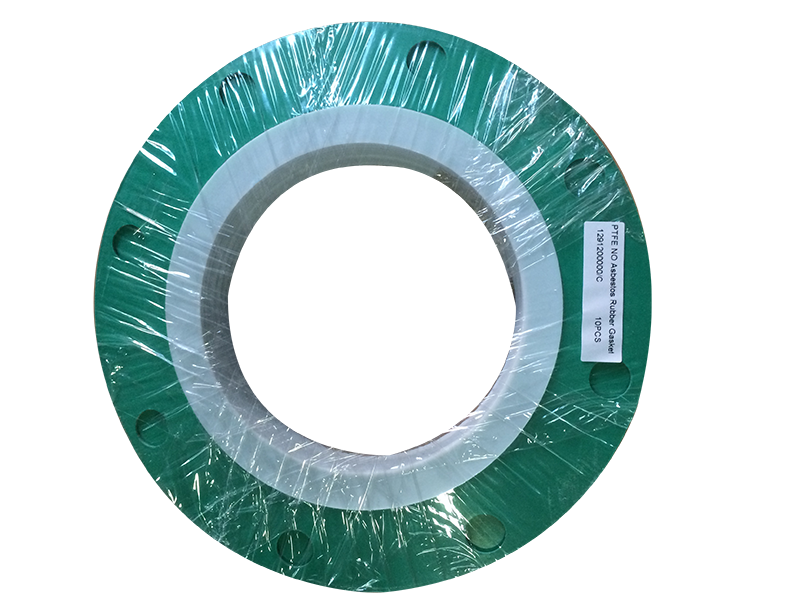

PTFE Ring Gaskets – A Reliable Solution For The Engaging Industries

Tips On Fitting A PTFE Ring Gasket In The Flange Joints

Our rewards are reduce selling prices,dynamic revenue team,specialized QC,sturdy factories,superior quality services for Top Grade Ptfe Coated Ring Joint Gasket - China Factory for Dry Break Couplings - 100% virgin PTFE Extrued Rod – Lucky Star Seal – Lucky Star Seal, The product will supply to all over the world, such as: Jamaica , Sweden , Istanbul , Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.