Super Lowest Price Plastic Seal Gasket - China OEM High Quality Urea Dispenser - Full Specification PTFE Rod – Lucky Star Seal – Lucky Star Seal Detail:

Technical Data:

| Properties | Unit | Result |

| Apparent density | g/cm3 | 2.3±0.1 |

| Tensile strength (min) | Mpa | ≥25 |

| Ultimate elongation (min) | % | ≥200 |

| Working Temp | °C | -180 ~ 260 |

| Produce Max. Temp | °C | 385 |

| Melting point | °C | 327 |

| Hardness Rockwell | - | M65 |

Supply size:

|

Type |

Diameter (mm) |

Length (mm) |

|

Extruded rod |

4–100 |

As customized |

|

110–200 |

As customized |

|

|

Moulded rod |

50–300 |

300 max |

Advantages:

♦ Superior endurance in corrosion

♦ Non-flammable,limited oxygen index is under 90.

♦ Low friction coefficient

♦ Non-viscous, Self-lubricating

♦ Superior endurance in high & low temperature, can be used -200~260℃

♦ High electrical insulation

♦ Atmospheric aging resistance

♦ Low permeability, good gas barrier property

♦ Good physiological compatibility and anti-thrombotic

Applications:

♦ Corrosion resistance: widely used in all chemical containers and parts which contacted with corrosive media, such as tanks, reactors, equipment lining, valves, pumps, fittings, filter materials, separation materials and pipe for corrosive fluids.

♦ Abrasion resistance: can be used as a self lubricating bearing, piston rings, seal rings, gaskets, valve seats, sliders and rails etc..

♦ Insulation materials: mainly used in the manufacture of various products with high temperature resistance, high-frequency resistance, electrical insulation and arc resistance, such as high-frequency cables, moisture-resistant cables, capacitor coils, insulating cover for wire, etc..

♦ Medical materials: such as artificial blood vessels, heart, esophagus, peritoneum, heart devices, a variety of intubation tubes and catheters.

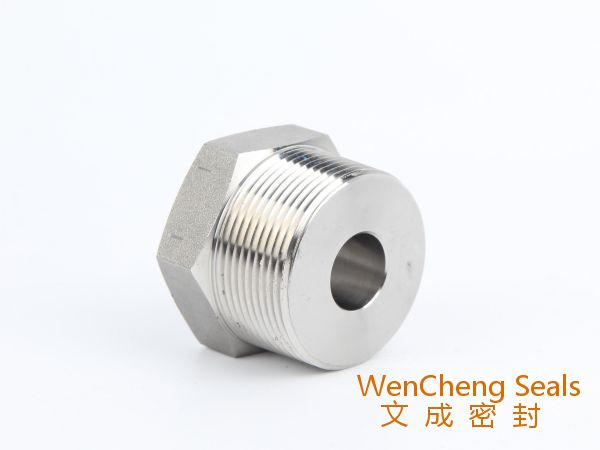

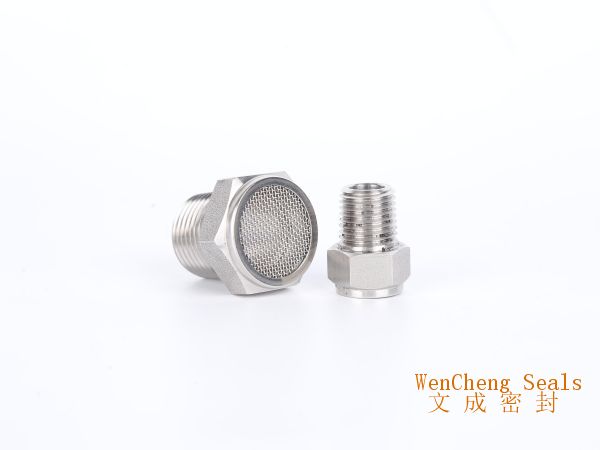

Product detail pictures:

Related Product Guide:

What Is A PTFE Ring Gasket?

Thermal And Chemical Benefits Of PTFE Ring Gaskets

Our growth depends on the superior equipment ,exceptional talents and continuously strengthened technology forces for Super Lowest Price Plastic Seal Gasket - China OEM High Quality Urea Dispenser - Full Specification PTFE Rod – Lucky Star Seal – Lucky Star Seal, The product will supply to all over the world, such as: Belgium , Estonia , South Korea , Upon today, we have customers from all over the world, including USA, Russia, Spain, Italy, Singapore, Malaysia, Thailand, Poland, Iran and Iraq. The mission of our company is to provide the highest quality products with best price. We are looking forward to doing business with you!

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.

-

Chinese wholesale Ptfe Non-asbestos Gasket - S...

-

Big Discount Ptfe Plastic Sheet - Factory best...

-

Good quality Submersible Pump Price - China OE...

-

China New Product Ptfe Spring Seal Ring - Shaf...

-

New Delivery for Gasket Ptfe Thread Seal Tape -...

-

Factory Selling Flat Teflon Gasket - 2”Airline...