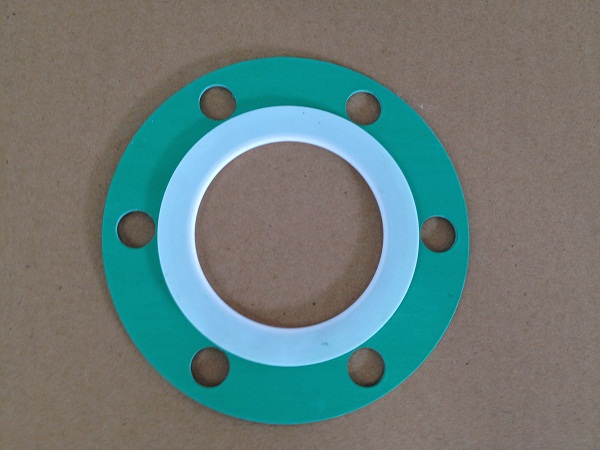

Rapid Delivery for Pure Ptfe Flange Gasket - FEP Encapsulated Silicone Manlid seals – Lucky Star Seal Detail:

Encapsulation

FEP

The most versatile when considering overall corrosion resistance, sealing capability and temperature.Temperature range -450 to + 400 degrees F. (-267 to 205 degrees C)

PFA

A fluorocarbon copolymer similar to FEP but it also offers greatly improved mechanical and creep properties at elevated operating temperatures. Temperature range -450 to +500 degrees

F. (-267 to +260 degrees C).

Physical Properties of Encapsulated O-rings:

Core material:

Silicon rubber: 85-90A Viton elastomers: 90-95A

Hollow Silicone Rubber: 75-80A Water absorption: <0.01

Features:

1.Excellent chemical resistance, is suitable for almost all chemical medium (strong oxidation, reducing solvent);

2.Good corrosion resistance ( Strong acid and alkali solvent );

3.Good compression resistance ≥30%;

4.Low Coefficient of Friction (only 0.1 ~ 0.2);

5.Good resistance to dissolve (≤0.1%) ;

6.High pressure resistantance(up to 60Mpa );

7.Excellent sealing persistence , increase 500% life time.

Product detail pictures:

Related Product Guide:

Thermal And Chemical Benefits Of PTFE Ring Gaskets

What Is A PTFE Ring Gasket?

Well-run equipment, expert income workforce, and far better after-sales expert services; We are also a unified large family, anyone stick to the corporate value "unification, dedication, tolerance" for Rapid Delivery for Pure Ptfe Flange Gasket - FEP Encapsulated Silicone Manlid seals – Lucky Star Seal, The product will supply to all over the world, such as: Greece , Angola , South Korea , We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market.

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!