Quoted price for High Power Pressure Pump - Virgin PTFE Molded Sheet Teflon Sheet – Lucky Star Seal Detail:

INTRODUCTION:

Skived PTFE Sheet is manufactured by technique of compacting, sintering, rotary cutting with PTFE granular resin. It has good dielectric performance and non-aging, best anti chemistry corresion ability and wide applying intension range.

The thickness is 0.5 – 8mm.

ADVANTAGE:

1. Working termp -180 – +260℃

2. Excellent non-sticky property, it is easier to remove any foreign articles

3. Low friction coefficient

4. Anti-chemical corrosion property

5. Excellent electrical insulation

APPLICATION:

1. Cable wrapping under high voltage and high temperature

2. Sealing the electronic parts

3. Reaction kettle, storage tank, valve, container, liner and gasket

4. Corrosion-resistance liner, seal, dielectric materials etc

PROPERTIES:

| PROPERTIES |

UNIT | VALUE |

| Density | g/cm³ | 2.1 – 2.3 |

| Color | White | |

| Tensile Strength (min) | MPa | 15 |

| Crack Elongation (min) | % | 150 |

| Working Temp | ℃ | -180 – +260 |

| Melting Temp | ℃ | 327 |

| Produce Max Temp | ℃ | 385 |

| Dielectric Strength(min) | Kv/mm | 10 |

SPECIFICATION:

| Thickness (mm) | Width (mm) | Length (mm) |

| 0.5 – 8 | 850, 1000, 1200, 1500, 1800, 2000 | ≥500 |

Remarks:

—Other sizes, colors can be customized.

—Length, width and thickness tolerances may vary by manufacturer

PACKAGE: Wooden Case or Pallet

DELIVERY TIME & SAMPLES:

Delivery time: As your request,usually within 1 week

Free sample is available if you need.

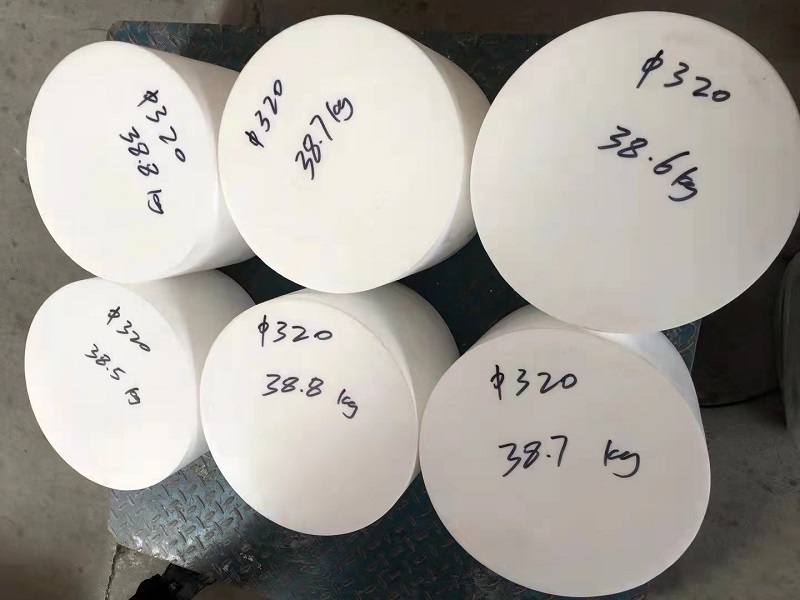

Product detail pictures:

Related Product Guide:

PTFE Ring Gaskets – A Reliable Solution For The Engaging Industries

All You Need To Know About The PTFE Ring Gasket

Well-run equipment, expert income workforce, and far better after-sales expert services; We are also a unified large family, anyone stick to the corporate value "unification, dedication, tolerance" for Quoted price for High Power Pressure Pump - Virgin PTFE Molded Sheet Teflon Sheet – Lucky Star Seal, The product will supply to all over the world, such as: Washington , Manchester , Malaysia , We sincerely hope to cooperate with customers all over the world, if you would like to have more information, please kindly contact us, we are looking forward to building up a great business relationship with you.

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.