OEM China Pump Seals Pump Mechanical Seal - 100% virgin PTFE Extrued Rod – Lucky Star Seal Detail:

Technical Data:

| Properties | Unit | Result |

| Apparent density | g/cm3 | 2.3±0.1 |

| Tensile strength (min) | Mpa | ≥25 |

| Ultimate elongation (min) | % | ≥200 |

| Working Temp | °C | -180 ~ 260 |

| Produce Max. Temp | °C | 385 |

| Melting point | °C | 327 |

| Hardness Rockwell | - | M65 |

Supply size:

|

Type |

Diameter (mm) |

Length (mm) |

|

Extruded rod |

4–100 |

As customized |

|

110–200 |

As customized |

|

|

Moulded rod |

50–300 |

300 max |

Advantages:

♦ Superior endurance in corrosion

♦ Non-flammable,limited oxygen index is under 90.

♦ Low friction coefficient

♦ Non-viscous, Self-lubricating

♦ Superior endurance in high & low temperature, can be used -200~260℃

♦ High electrical insulation

♦ Atmospheric aging resistance

♦ Low permeability, good gas barrier property

♦ Good physiological compatibility and anti-thrombotic

Applications:

♦ Corrosion resistance: widely used in all chemical containers and parts which contacted with corrosive media, such as tanks, reactors, equipment lining, valves, pumps, fittings, filter materials, separation materials and pipe for corrosive fluids.

♦ Abrasion resistance: can be used as a self lubricating bearing, piston rings, seal rings, gaskets, valve seats, sliders and rails etc..

♦ Insulation materials: mainly used in the manufacture of various products with high temperature resistance, high-frequency resistance, electrical insulation and arc resistance, such as high-frequency cables, moisture-resistant cables, capacitor coils, insulating cover for wire, etc..

♦ Medical materials: such as artificial blood vessels, heart, esophagus, peritoneum, heart devices, a variety of intubation tubes and catheters.

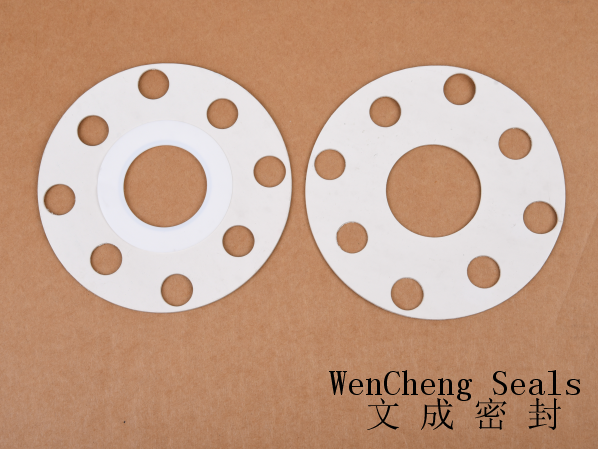

Product detail pictures:

Related Product Guide:

Tips On Fitting A PTFE Ring Gasket In The Flange Joints

What Is A PTFE Ring Gasket?

Dedicated to strict top quality command and considerate purchaser support, our experienced staff customers are always available to discuss your necessities and be certain full client gratification for OEM China Pump Seals Pump Mechanical Seal - 100% virgin PTFE Extrued Rod – Lucky Star Seal, The product will supply to all over the world, such as: Spain , El Salvador , Jersey , Insisting on the high quality generation line management and customers expert assistance, we now have designed our resolution to offer our buyers using the to start with amount getting and just after services practical experience. Maintaining the prevailing friendly relations with our buyers, we however innovate our solution lists all of the time to satisfy the brand new demands and adhere to the most up-to-date development of the market in Malta. We are ready to face the worries and make the improve to understand all the possibilities in international trade.

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,

-

Discount wholesale Seaflo Water Pump 12 Volt Dc...

-

Wholesale Dealers of Sealing Gaskets - Digital...

-

Factory Price Mini Booster Pump - Document Hol...

-

Reasonable price for Diaphragm Mini Vacuum Pump...

-

Supply OEM Dby Diaphragm Pump - OEM Colourful ...

-

New Arrival China 8 Inch Lay Flat Discharge Hos...