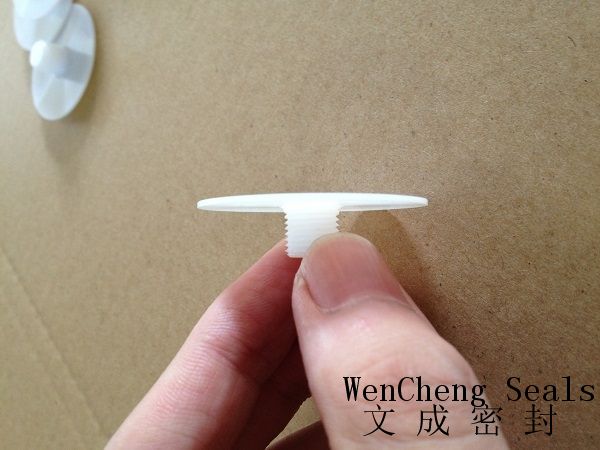

OEM China Ptfe Encapsulated Viton O-Ring - 1 1/2”Airline Ball Valve rear PTFE Part – Lucky Star Seal Detail:

Specifications:

Item:1 1/2”Airline Ball Valve rear PTFE Part

Color:White

Material: PTFE

Size: OEM with drawings

Weigth: 0.5~500g

Process: CNC machining

Property:

1.Best precision:0.02mm

2.Surface: flat and tidy,no defects of crevices layers and separation

3.Temperature range:-196℃ ~ 260℃

4.Chemical property:

A. aging resistance

B. radiation resistance

C. low permeability

D. high pressure resistance

E. oil resistance

F. anti-corrosion

Applications:

1.Sealing

2.Bushing

3.Medical device components

4.Electrical components

5. Pump and valve components

6.Food processing machinery components

Services:

1. Prompt delivery and consider services

2. Competitive price and high quality promise

3. ISO9000:2008/QS9000/SGS approved

4. OEM&ODM accepted

5. Rich experience in the design and manufacturing in PTFE seals.

Product detail pictures:

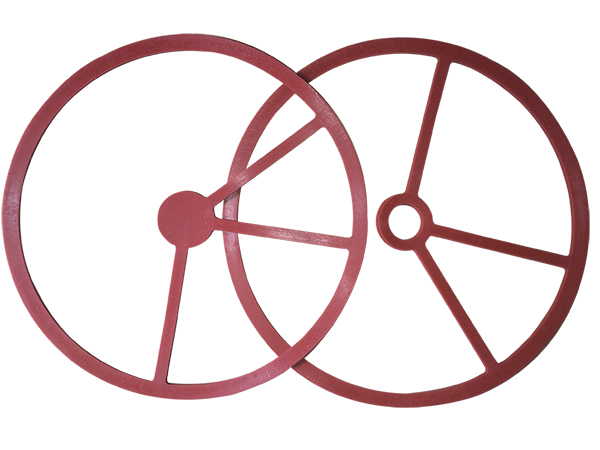

Related Product Guide:

What Is A PTFE Ring Gasket?

Thermal And Chemical Benefits Of PTFE Ring Gaskets

It adheres to the tenet "Honest, industrious, enterprising, innovative" to develop new products constantly. It regards customers, success as its own success. Let us develop prosperous future hand in hand for OEM China Ptfe Encapsulated Viton O-Ring - 1 1/2”Airline Ball Valve rear PTFE Part – Lucky Star Seal, The product will supply to all over the world, such as: New Zealand , Austria , Puerto Rico , Our product quality is one of the major concerns and has been produced to meet the customer's standards. "Customer services and relationship" is another important area which we understand good communication and relationships with our customers is the most significant power to run it as a long term business.

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.