ODM Supplier Teflon Silicone Gasket - China Factory for Dry Break Couplings - 100% virgin PTFE Extrued Rod – Lucky Star Seal – Lucky Star Seal Detail:

Technical Data:

| Properties | Unit | Result |

| Apparent density | g/cm3 | 2.3±0.1 |

| Tensile strength (min) | Mpa | ≥25 |

| Ultimate elongation (min) | % | ≥200 |

| Working Temp | °C | -180 ~ 260 |

| Produce Max. Temp | °C | 385 |

| Melting point | °C | 327 |

| Hardness Rockwell | - | M65 |

Supply size:

|

Type |

Diameter (mm) |

Length (mm) |

|

Extruded rod |

4–100 |

As customized |

|

110–200 |

As customized |

|

|

Moulded rod |

50–300 |

300 max |

Advantages:

♦ Superior endurance in corrosion

♦ Non-flammable,limited oxygen index is under 90.

♦ Low friction coefficient

♦ Non-viscous, Self-lubricating

♦ Superior endurance in high & low temperature, can be used -200~260℃

♦ High electrical insulation

♦ Atmospheric aging resistance

♦ Low permeability, good gas barrier property

♦ Good physiological compatibility and anti-thrombotic

Applications:

♦ Corrosion resistance: widely used in all chemical containers and parts which contacted with corrosive media, such as tanks, reactors, equipment lining, valves, pumps, fittings, filter materials, separation materials and pipe for corrosive fluids.

♦ Abrasion resistance: can be used as a self lubricating bearing, piston rings, seal rings, gaskets, valve seats, sliders and rails etc..

♦ Insulation materials: mainly used in the manufacture of various products with high temperature resistance, high-frequency resistance, electrical insulation and arc resistance, such as high-frequency cables, moisture-resistant cables, capacitor coils, insulating cover for wire, etc..

♦ Medical materials: such as artificial blood vessels, heart, esophagus, peritoneum, heart devices, a variety of intubation tubes and catheters.

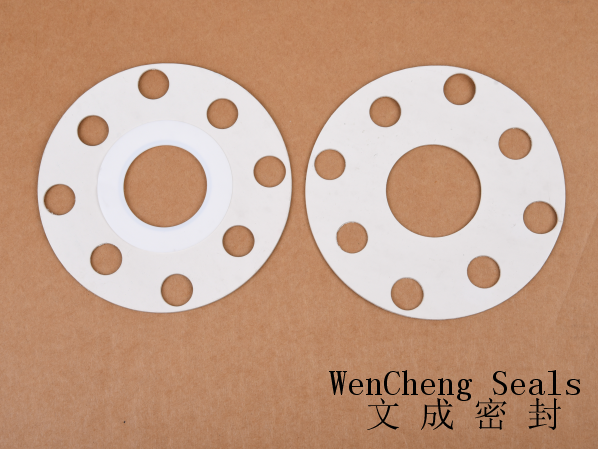

Product detail pictures:

Related Product Guide:

All You Need To Know About The PTFE Ring Gasket

What Is A PTFE Ring Gasket?

"Control the standard by the details, show the power by quality". Our organization has strived to establish a highly efficient and stable employees team and explored an effective high-quality command method for ODM Supplier Teflon Silicone Gasket - China Factory for Dry Break Couplings - 100% virgin PTFE Extrued Rod – Lucky Star Seal – Lucky Star Seal, The product will supply to all over the world, such as: Mumbai , Netherlands , Karachi , Adhering to the principle of "Enterprising and Truth-Seeking, Preciseness and Unity", with technology as the core, our company continues to innovate, dedicated to providing you with the highest cost-effective products and meticulous after-sales service. We firmly believe that: we are outstanding as we are specialized.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.