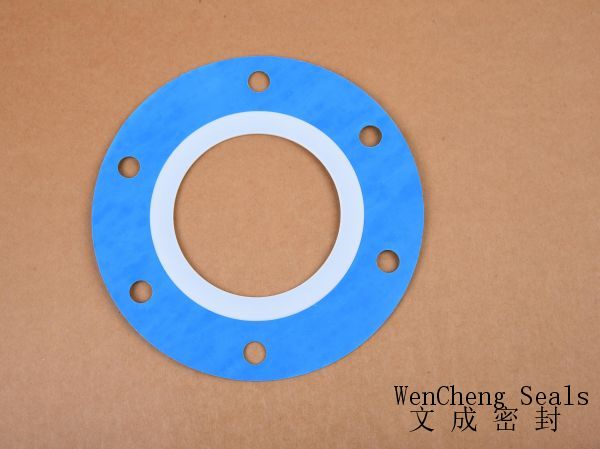

Manufacturing Companies for Deep Water Pump - FEP Encapsulated Silicone Manlid seals – Lucky Star Seal Detail:

Encapsulation

FEP

The most versatile when considering overall corrosion resistance, sealing capability and temperature.Temperature range -450 to + 400 degrees F. (-267 to 205 degrees C)

PFA

A fluorocarbon copolymer similar to FEP but it also offers greatly improved mechanical and creep properties at elevated operating temperatures. Temperature range -450 to +500 degrees

F. (-267 to +260 degrees C).

Physical Properties of Encapsulated O-rings:

Core material:

Silicon rubber: 85-90A Viton elastomers: 90-95A

Hollow Silicone Rubber: 75-80A Water absorption: <0.01

Features:

1.Excellent chemical resistance, is suitable for almost all chemical medium (strong oxidation, reducing solvent);

2.Good corrosion resistance ( Strong acid and alkali solvent );

3.Good compression resistance ≥30%;

4.Low Coefficient of Friction (only 0.1 ~ 0.2);

5.Good resistance to dissolve (≤0.1%) ;

6.High pressure resistantance(up to 60Mpa );

7.Excellent sealing persistence , increase 500% life time.

Product detail pictures:

Related Product Guide:

Tips On Fitting A PTFE Ring Gasket In The Flange Joints

All You Need To Know About The PTFE Ring Gasket

We have now sophisticated machines. Our solutions are exported to the USA, the UK and so on, enjoying a great reputation amid consumers for Manufacturing Companies for Deep Water Pump - FEP Encapsulated Silicone Manlid seals – Lucky Star Seal, The product will supply to all over the world, such as: Indonesia , Gambia , Serbia , We care about every steps of our services, from factory selection, product development & design, price negotiation, inspection, shipping to aftermarket. Now we have implemented a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our solutions have been strictly inspected before shipment. Your Success, Our Glory: Our aim is to help customers realize their goals. We're making great efforts to achieve this win-win situation and sincerely welcome you to join us.

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.

-

Supply OEM/ODM Teflon Valve Parts - Price Shee...

-

Low price for Butterfly Valve Front Ptfe - 11/...

-

OEM Supply Ptfe Sheets - PTFE/CNAF Gasket (Blu...

-

High Performance Brass Quick Coupling ( Type A ...

-

Trending Products Ptfe Gasket Sealing Compound ...

-

Factory supplied Enveloped Ptfe Gasket - Solen...