China OEM Bonded Seal Pump Mechanical Seal - China OEM High Quality Urea Dispenser - Full Specification PTFE Rod – Lucky Star Seal – Lucky Star Seal Detail:

Technical Data:

| Properties | Unit | Result |

| Apparent density | g/cm3 | 2.3±0.1 |

| Tensile strength (min) | Mpa | ≥25 |

| Ultimate elongation (min) | % | ≥200 |

| Working Temp | °C | -180 ~ 260 |

| Produce Max. Temp | °C | 385 |

| Melting point | °C | 327 |

| Hardness Rockwell | - | M65 |

Supply size:

|

Type |

Diameter (mm) |

Length (mm) |

|

Extruded rod |

4–100 |

As customized |

|

110–200 |

As customized |

|

|

Moulded rod |

50–300 |

300 max |

Advantages:

♦ Superior endurance in corrosion

♦ Non-flammable,limited oxygen index is under 90.

♦ Low friction coefficient

♦ Non-viscous, Self-lubricating

♦ Superior endurance in high & low temperature, can be used -200~260℃

♦ High electrical insulation

♦ Atmospheric aging resistance

♦ Low permeability, good gas barrier property

♦ Good physiological compatibility and anti-thrombotic

Applications:

♦ Corrosion resistance: widely used in all chemical containers and parts which contacted with corrosive media, such as tanks, reactors, equipment lining, valves, pumps, fittings, filter materials, separation materials and pipe for corrosive fluids.

♦ Abrasion resistance: can be used as a self lubricating bearing, piston rings, seal rings, gaskets, valve seats, sliders and rails etc..

♦ Insulation materials: mainly used in the manufacture of various products with high temperature resistance, high-frequency resistance, electrical insulation and arc resistance, such as high-frequency cables, moisture-resistant cables, capacitor coils, insulating cover for wire, etc..

♦ Medical materials: such as artificial blood vessels, heart, esophagus, peritoneum, heart devices, a variety of intubation tubes and catheters.

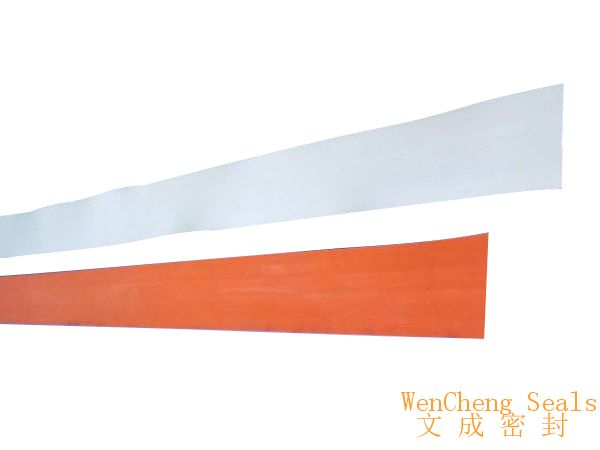

Product detail pictures:

Related Product Guide:

Tips On Fitting A PTFE Ring Gasket In The Flange Joints

Thermal And Chemical Benefits Of PTFE Ring Gaskets

Now we have superior devices. Our solutions are exported to your USA, the UK and so on, enjoying a superb name between customers for China OEM Bonded Seal Pump Mechanical Seal - China OEM High Quality Urea Dispenser - Full Specification PTFE Rod – Lucky Star Seal – Lucky Star Seal, The product will supply to all over the world, such as: Seychelles , Portugal , Serbia , Our company offers the full range from pre-sales to after-sales service, from product development to audit the use of maintenance, based on strong technical strength, superior product performance, reasonable prices and perfect service, we will continue to develop, to provide the high-quality products and services, and promote lasting cooperation with our customers, common development and create a better future.

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.

-

High Quality Automatic Booster Pump - Stainles...

-

Factory Price For Expanded Ptfe Gasket Tape - ...

-

Best Price for Ptfe Rubber Oil Seal - Fully La...

-

Super Lowest Price Lab Vacuum Diaphragm Pump - ...

-

Factory Promotional Extruded Ptfe Teflon Bar - ...

-

High Quality Empaquetaduras Para Bombas - Best...