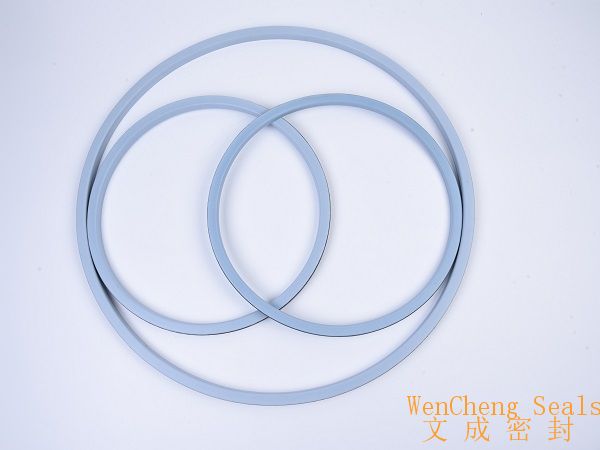

China Factory for Dry Break Couplings - FEP Encapsulated Silicone Manlid seals – Lucky Star Seal Detail:

Encapsulation

FEP

The most versatile when considering overall corrosion resistance, sealing capability and temperature.Temperature range -450 to + 400 degrees F. (-267 to 205 degrees C)

PFA

A fluorocarbon copolymer similar to FEP but it also offers greatly improved mechanical and creep properties at elevated operating temperatures. Temperature range -450 to +500 degrees

F. (-267 to +260 degrees C).

Physical Properties of Encapsulated O-rings:

Core material:

Silicon rubber: 85-90A Viton elastomers: 90-95A

Hollow Silicone Rubber: 75-80A Water absorption: <0.01

Features:

1.Excellent chemical resistance, is suitable for almost all chemical medium (strong oxidation, reducing solvent);

2.Good corrosion resistance ( Strong acid and alkali solvent );

3.Good compression resistance ≥30%;

4.Low Coefficient of Friction (only 0.1 ~ 0.2);

5.Good resistance to dissolve (≤0.1%) ;

6.High pressure resistantance(up to 60Mpa );

7.Excellent sealing persistence , increase 500% life time.

Product detail pictures:

Related Product Guide:

Thermal And Chemical Benefits Of PTFE Ring Gaskets

Tips On Fitting A PTFE Ring Gasket In The Flange Joints

We now have our individual sales group, layout team, technical team, QC crew and package group. Now we have strict high-quality control procedures for each procedure. Also, all of our workers are experienced in printing discipline for China Factory for Dry Break Couplings - FEP Encapsulated Silicone Manlid seals – Lucky Star Seal, The product will supply to all over the world, such as: Moscow , Namibia , South Korea , Why we can do these? Because: A, We are honest and reliable. Our products have high quality, attractive price, sufficient supply capacity and perfect service. B, Our geographical position has a big advantage . C, Various types: Welcome your inquiry, It will be highly appreciated.

The company's products can meet our diverse needs, and the price is cheap, the most important is that the quality is also very nice.