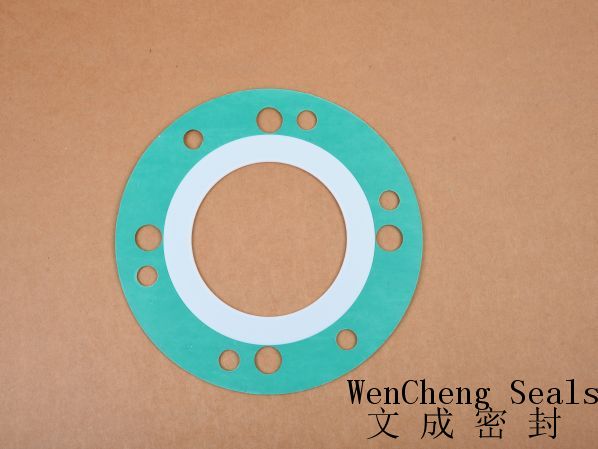

Big discounting Flange Insulation Gasket - Virgin PTFE Molded Sheet Teflon Sheet – Lucky Star Seal Detail:

INTRODUCTION:

Skived PTFE Sheet is manufactured by technique of compacting, sintering, rotary cutting with PTFE granular resin. It has good dielectric performance and non-aging, best anti chemistry corresion ability and wide applying intension range.

The thickness is 0.5 – 8mm.

ADVANTAGE:

1. Working termp -180 – +260℃

2. Excellent non-sticky property, it is easier to remove any foreign articles

3. Low friction coefficient

4. Anti-chemical corrosion property

5. Excellent electrical insulation

APPLICATION:

1. Cable wrapping under high voltage and high temperature

2. Sealing the electronic parts

3. Reaction kettle, storage tank, valve, container, liner and gasket

4. Corrosion-resistance liner, seal, dielectric materials etc

PROPERTIES:

| PROPERTIES |

UNIT | VALUE |

| Density | g/cm³ | 2.1 – 2.3 |

| Color | White | |

| Tensile Strength (min) | MPa | 15 |

| Crack Elongation (min) | % | 150 |

| Working Temp | ℃ | -180 – +260 |

| Melting Temp | ℃ | 327 |

| Produce Max Temp | ℃ | 385 |

| Dielectric Strength(min) | Kv/mm | 10 |

SPECIFICATION:

| Thickness (mm) | Width (mm) | Length (mm) |

| 0.5 – 8 | 850, 1000, 1200, 1500, 1800, 2000 | ≥500 |

Remarks:

—Other sizes, colors can be customized.

—Length, width and thickness tolerances may vary by manufacturer

PACKAGE: Wooden Case or Pallet

DELIVERY TIME & SAMPLES:

Delivery time: As your request,usually within 1 week

Free sample is available if you need.

Product detail pictures:

Related Product Guide:

Tips On Fitting A PTFE Ring Gasket In The Flange Joints

What Is A PTFE Ring Gasket?

We are proud of the high customer satisfaction and wide acceptance due to our persistent pursuit of high quality both on product and service for Big discounting Flange Insulation Gasket - Virgin PTFE Molded Sheet Teflon Sheet – Lucky Star Seal, The product will supply to all over the world, such as: Gambia , Macedonia , Japan , We have our own registered brand and our company is developing rapidly owing to high quality products, competitive price and excellent service. We sincerely hope to establish business relations with more friends from home and abroad in the near future. We look forward to your correspondence.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!